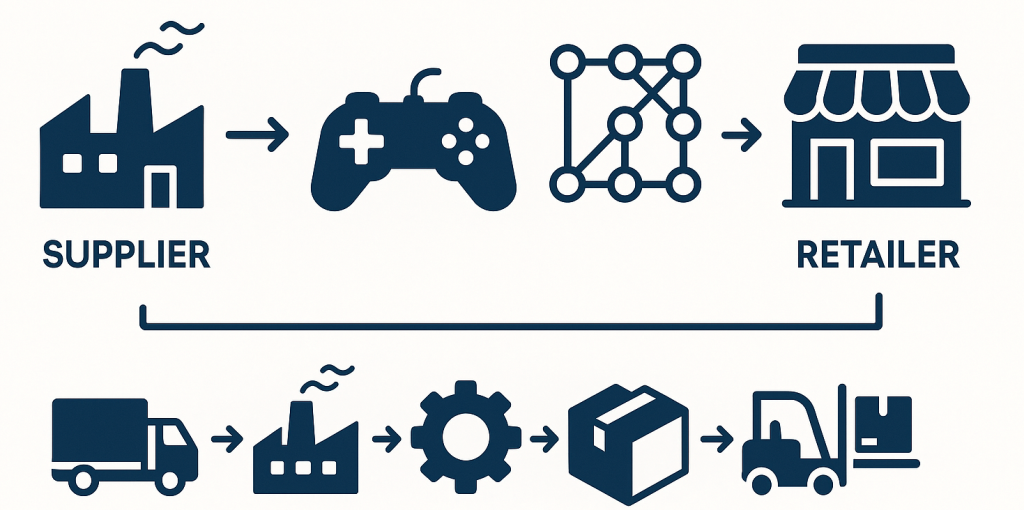

In an increasingly complex and interconnected world, managing a supply chain isn’t just about logistics — it’s about strategy. Decisions made by one company can create ripple effects across an entire network of suppliers, manufacturers, distributors, and retailers. So, how do you make the best decisions when the actions of others can directly impact your outcomes? That’s where game theory comes in.

Game theory is a branch of mathematics and economics that studies how people or organizations make decisions in situations where the outcome depends not only on their own actions but also on the actions of others. In supply chain, game theory provides an essential tool to coordinate the process.

Each player in the chain wants to minimize costs and maximize profits. But these players often have conflicting interests. For instance, a manufacturer may want to place large, infrequent orders to reduce setup costs, while a supplier may prefer smaller, regular orders to smooth production. Here, game theory helps model these conflicting goals and find a strategic equilibrium.[1]

1. Introduction to Game Theory

There are different kinds of game theory. Here are some typical game theory models.

Cooperative Game:

In a cooperative game, players can form binding agreements (coalitions) to coordinate actions and share profits or cost savings. Typical tools to manage cooperative games include the Shapley Value, Core, and Nucleolus, which are methods designed to fairly allocate the gains from cooperation.

Non-Cooperative Game:

In a non-cooperative game, each supply chain participant acts independently, aiming to maximize their own payoff without any cooperation with others. The core concept is the Nash equilibrium, where no player can improve their outcome by unilaterally changing their strategy.

Stackelberg Game (Leader-Follower Model):

In the Stackelberg game, one player acts as the leader by moving first, while others act as followers, observing the leader’s action and then reacting optimally. Mathematically, Stackelberg games are often solved using backward induction.

Nash Bargaining Game:

In the Nash bargaining game, two players negotiate the division of a surplus generated through cooperation. The solution concept, known as the Nash Bargaining Solution, aims to maximize the product of the players’ gains relative to their disagreement points.

2. Application in supply chain

There are several applications of game theory utilized in supply chain.

- Pricing Strategies

Game theory helps retailers and manufacturers decide on competitive pricing, promotions, or discounts without entering destructive price wars. - Inventory Management

Firms can model how much inventory to hold based on others’ behavior—like anticipating demand fluctuations caused by a competitor’s promotional campaign. - Contract Negotiations

Contracts like buy-back agreements, revenue sharing, or quantity discounts can be designed using game theory to align incentives across the supply chain. - Risk Sharing

During disruptions (e.g., pandemics, geopolitical issues), game-theoretic models can help firms collaborate on risk mitigation by sharing critical resources or information

3. Research Trends

Several emerging trends are capturing attention in this field. Firstly, as society becomes increasingly concerned with sustainability, game theory is widely applied in supply chains to manage the conflict between profit generation and emissions reduction[2].

Figure 1: Green Supply Chain, generated using ChatGPT

Secondly, as supply chains become more digitized and data-driven, AI and game theory are converging to create predictive models that simulate strategic behavior at scale, leading to more resilient, agile, and optimized supply chains.

We can expect the adoption of game theory to increase in the future.

An article by Lingyu Zhang.

References:

[1] Cachon, G. P., & Netessine, S. (2006). Game theory in supply chain analysis. Models, methods, and applications for innovative decision making, 200-233.

[2] Agi, M. A., Faramarzi-Oghani, S., & Hazır, Ö. (2021). Game theory-based models in green supply chain management: a review of the literature. International journal of production research, 59(15), 4736-4755.